How to Use MIG to Weld Stainless Steel: From Setup to Finish

Stainless steel is one of the most widely used materials among professionals and DIY sets for quality, long-lasting welding. MIG welding stainless steel—if you have the skill, you may be looking to perfect your mastery of this form of fabrication and metallurgy. Whether you are taking on a construction assignment, tinkering with machinery or fabricating a complex stainless steel object, a perfect weld starts with the right manufacturer such as UDO Welding who deals with high quality stainless steel welding rods for perfect welding.

Note: Discover the best stainless steel welding wire with us! As an authorized dealer of all major brands used by professionals, we offer the largest stock of welding supplies. Visit our website at https://www.udo.co.th/product/detail/yawata-316l-16 to explore our products or seek expert welding advice from our specialists. Don’t miss out on the highest quality and availability in the market!

In this guide, we are going to walk you through how to MIG weld stainless steel – from setup to execution and finishing techniques that will deliver lifetime quality results.

So let the article read all about MIG welding stainless steel.

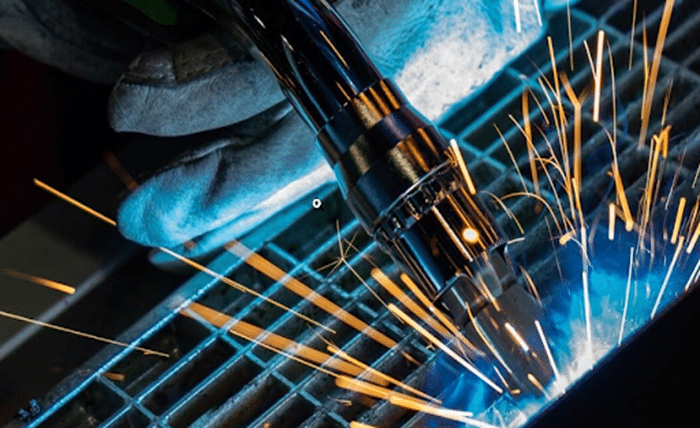

Gas Metal Arc Welding, better known as MIG (Metal Inert Gas) welding, is a much more versatile and easier method of joining stainless steel than any other available methods. It uses a consumable electrode and is assisted by a shielding gas to shield the weld pool from contamination So the resulting joint is clean, strong, and attractive, well suited to the positive characteristics of stainless steel: its corrosion resistance and tough workability.

Stainless steels behave differently from other materials, and if proper care is not taken, the weld may simply distort or discolor, or the joint may be weak. Using quality stainless steel welding rods like the Yawata 316L-16 pictured above are essential for strength and a nice professional looking finish

STEP 1: SETTING UP YOUR MIG WELDING GEAR

Select the Right Equipment

First of all, you will need a MIG welding machine that can work with stainless steel. Make sure it has adjustable amperage, wire feed speed, and voltage settings, because these will impact your quality of weld. When using the machine, make sure to use high-grade stainless steel rods such as the ones available through UDO Welding for best performance.

Selecting the appropriate shielding gas

Shielding gas keeps your weld from being contaminated by the atmosphere. The perfect gas will need to be CO2 (usually around 2%) mixed with argon—somewhere in the vicinity of 98% argon and 2% CO2 are ideal for welding stainless steel with MIG. All this helps to minimize spatter and facilitates smooth arcs for a clean weld.

Clean the Base Metal

When welding stainless steel, cleanliness is of utmost importance. Any contaminants such as oil, dirt or rust can cause poor-quality welds. Finally, scrub the area with a stainless steel wire brush or grinder to get rid of any surface contaminants first, then wipe the area down with solvent to prepare.

Step 2: Learning the Welding Process

Set the Right Parameters

How you calibrate your welding machine directly correlates to how well your MIG welding project performs. And for stainless steel, stick to the lower heat settings to avoid warping and dulling. Tune your wire feed speed and voltage until you get a steady arc.

Hold the Right Angle and Distance

For the best control keep your welding gun at a 10–15 degree angle to the workpiece. Maintaining a distance of approximately ⅜ inch (9.5 mm) between the gun nozzle and the material ensures a stable arc and helps eliminate spatter.

Focus on Travel Speed

Stainless steel MIG welding needs a steady hand and steady motion. If your hand is moving too fast then have weak welds, if it is moving too slow then the heat will build up so much that the workpiece gets distorted or burnt through. As with all things, work for a moderate, consistent travel speed for optimum results.

Step 3: Final Touch for Professional Results

Inspect the Weld

You are loading data only up to October 2023. There should be little spatter, smooth edges, no visible cracks, and no visible gaps in a good weld. If you have weak areas, rework them with a welding machine.

Remove Discoloration

Heat stains can leave unsightly marks that are hard to get off on stainless steel. Renaissance wax or a stainless steel pickling paste or polish can be applied to restore the natural luster of the metal. This step enhances both looks as well as corrosion resistance.

Protect the Weld

Welded area is treated with a passivation solution to improve the corrosion resistance. Passivation strips away surface contamination and helps a protective oxide layer form, a process critical in the long life of stainless steel.

What Makes Yawata 316L-16 Stainless Steel Welding Rods Stand Out?

No matter what you are welding up with your MIG welder and stainless steel rods, the quality of your weld rods can make or break the job. Available at UDO Welding, Yawata 316L-16 stainless steel welding rods are built for precision work. These rods are mostly used in high-corrosion environments, requiring excellent weldability and a strong, durable finish.

Advantages of Yawata 316L-16 rods are:

Avoiding Corrosion: Ideal for marine, chemical and industrial uses.

Superior Weld Strength: Keeps joints together, even under the most extreme conditions

Easy To Use: Perfect for both professionals and amateurs

High-quality welding rods pay off тhat they potentially improve your work so that, afterwards, you do not deal with costly rework or repair work.

Take Your MIG Welding Stainless Steel Projects to The Next Level

Mastering MIG welding for stainless steel requires practice, precision and the right materials. With the guidance of this guide and the purchase of high-quality stainless steel welding rods such as Yawata 316L-16, you will be a decent step towards perfecting your welds, ensuring strength and durability.

Are you ready to begin your next stainless steel welding job? Head over to UDO Welding to check out their collection of premium welding products to find what you need in your home. Whether you are a veteran or a DIYer, UDO Welding has all you need to work with closer to perfection, from the setup to the finish.